Octobre à Düsseldorf - Rendez-vous au K 2025

RALLYCHEM continues to advance its technological innovation, collaborating closely with partners across the industrial chain to drive the evolution of material applications through cutting-edge polymer science.

As a world-leading manufacturer of polyester homopolymers and polyester waxes, RALLYCHEM is dedicated to improving everyday life through technology.

Our solutions serve industries including plastics, asphalt, adhesives, textiles, coatings, leather, and inks — offering the latest, most comprehensive solutions to help our clients succeed efficiently in a rapidly changing market.

Compared with polyolefins, ester-based materials naturally provide superior heat resistance.

By designing the main carbon chain and selecting specific acids and alcohols for esterification, we synthesize functional and targeted polyester waxes.

Our product line — including the RL-1116 Series, RL-60A, RL-32, RL-70, and RL-691 Series — offers excellent lubrication for plastic processing.

Notably, the RL-691 Series serves as a unique high-temperature plastic lubricant that can replace natural montan wax — ideal for engineering plastics such as PA, PC, PET, PU, and epoxy resins.

Advantages:

Oxidized polyethylene wax is an extremely efficient plastic lubricant, suitable for PVC, CPVC, engineering plastics, and rubber modification.

It provides continuous lubrication throughout processing — from start to finish.

In wax emulsion production, RALLYCHEM offers customized melting points, acid values, and viscosities tailored to specific formulations and process needs.

Traditional impact modifiers like CPE, ACR, and MBS each have limitations:

RALLYCHEM’s Polyester Homopolymer Series outperforms all these traditional modifiers — achieving a new generation of impact enhancement and helping manufacturers gain a competitive edge.

Advantages:

Our polyolefin waxes (RL-1002, RL-2063, RL-200, RL-617A, and RL-001) feature excellent flowability, dispersion, and low thermal weight loss.

They are ideal for use in plastics, masterbatches, rubbers, adhesives, and water-based wax emulsions.

RALLYCHEM micronized waxes are widely used in powder coatings, coil coatings, pressed powder cosmetics, wood finishes, printing inks, and pigment dispersions.

These spherical, uniformly sized wax particles ensure excellent dispersion and are available in customized melting points and acid values to meet diverse industrial needs.

Leveraging our proprietary ester synthesis technology, RALLYCHEM has developed bio-based oligomeric polyester plasticizers as sustainable alternatives to DOTP.

These plasticizers are phthalate-free, environmentally friendly, and widely used in flexible PVC products.

Advantages:

As one of the world’s key producers of water-based wax additives, RALLYCHEM products play vital roles in textile yarn protection, surface enhancement for inks and coatings, leather finishing, and mold release for rubber, metal, and paper.

Advantages:

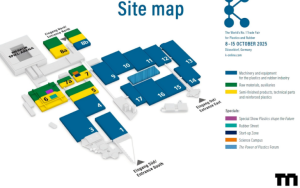

See You in Germany!

October 8–15, 2025

Messe Düsseldorf, Germany

RALLYCHEM Booth: Hall 7.1, A45

Vous pouvez être intéressé

Lubrification des plastiques techniques : Pourquoi la cire polyester est l'alternative à la cire Montan

2026 / 01 / 23

Optimisation de la durabilité des revêtements avec les additifs de cire avancés de RallyChem

2026 / 01 / 22

Qu'est-ce qu'un lubrifiant pour PVC et pourquoi est-il essentiel dans la transformation du PVC ?

2025 / 12 / 31

Amélioration des performances de surface des revêtements modernes grâce à la cire de polyéthylène oxydée

2025 / 12 / 30

Choisir le bon partenaire pour la cire de polyéthylène oxydé pour le CPVC - Ce qui compte vraiment et comment Rallychem le fait

2025 / 12 / 15

Pour toute demande de renseignements, veuillez appeler

Rallychem se fera un plaisir de vous aider !

+86 13456396233