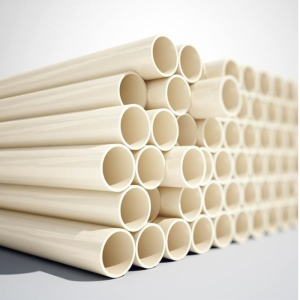

RLWAX® high performance lubricant additives set a new standard in the production of PVC foamed products. We focus on the wetting and dispersing properties of the lubricant to ensure better integration between the PVC resin particles, calcium carbonate and processing aids to achieve the desired plasticization state.

Improved Surface Finish

Reduced Overall Costs

Improved Production Stability

Extend Start-up Tim

Internal/External Lubrication and Mold Release

Rallychem Chemicals vous fournira des services de conseil professionnel, des services de solutions personnalisées pour le PVC/CPVC, des additifs de cire, des émulsions de cire, des services de production personnalisée de micro-polymères, n'hésitez pas à nous contacter.

Nous contacter

Pour toute demande de renseignements, veuillez appeler

Rallychem se fera un plaisir de vous aider !

+86 13456396233