PVC加工における酸化ポリエチレンワックスの酸価とは?

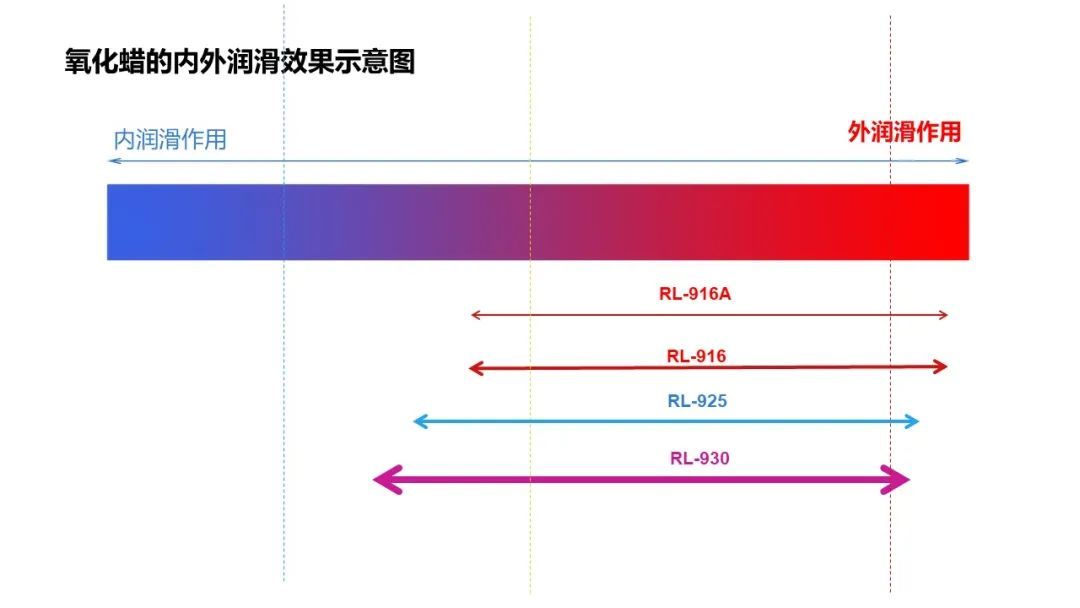

Oxidized polyethylene waxes are used as both internal and external PVC lubricants. There are a number of common models on the market, such as 916, 925 and 930, which represent acid value 16, acid value 25 and acid value 30, respectively.

Generally speaking, the acid value represents the polarity of the oxidized wax and is positively correlated. The higher the acid value, the higher the polarity of the oxidized wax. In practical PVC processing, a higher acid value means that the oxidized wax has a more pronounced internal lubrication effect and increases the speed of plasticization. For example, the plasticizing speed of 930 with acid value 30 is significantly faster than that of 916 with acid value 16, so it is more suitable for PVC products with higher plasticizing requirements, such as SPC flooring, stone wall panels and other highly filled products.

On the other hand, when the acid value of oxidized polyethylene wax is higher, it is more in favor of internal lubrication, and its external lubrication effect will be relatively weakened. Therefore, oxidized polyethylene waxes with low acid values are more suitable for PVC products with high demands on post-molding and surface. For example, shrink films, calendered sheets, etc.

Therefore, 916A with an acid value of 16 can be used as a good late release agent after plasticization has reached the required level.

ご興味があるかもしれません

Engineering Plastics Lubrication: Why Polyester Wax is the Montan Wax Alternative

2026 / 01 / 23

ラリーケムの高度なワックス添加剤によるコーティング耐久性の最適化

2026 / 01 / 22

PVC潤滑剤とは何か、なぜPVC加工に不可欠なのか?

2025 / 12 / 31

酸化ポリエチレンワックスによる最新コーティングの表面性能向上

2025 / 12 / 30

CPVC用酸化ポリエチレンワックスパートナーの正しい選択 - 何が本当に重要か、そしてラリーケムはどのように提供するか

2025 / 12 / 15