Anti-separation, high dispersion, special lubricant for PVC high filled products

Polyester wax as PVC internal lubricant has natural compatibility and dispersibility advantages, which is more recommended for the production of PVC highly filled products.

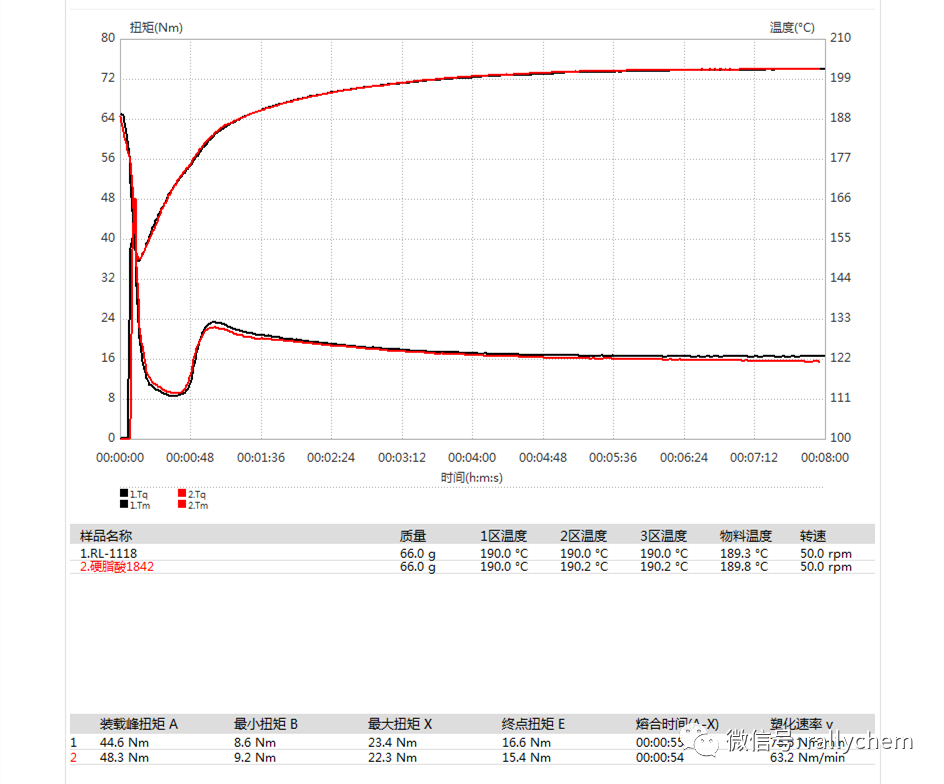

Compared with stearic acid, RL-1118 has obvious cost performance.

CaCO3 belongs to inorganic filler, which is an excellent PVC filler modifier. It can obviously increase the hardness of PVC products, but also can effectively reduce the cost. Affordable and highly filled PVC products have appeared more and more in our lives.

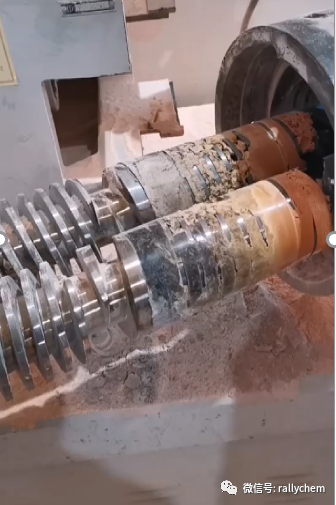

In the production process of highly filled PVC products, the high content of CaCO3 in the screw strong shear generates a lot of frictional heat, which can easily lead to the decomposition of PVC coke; at the same time, the plasticizing dispersion is not uniform, the grams of weight imbalance is also a common problem in the production.

90% of the heat of plasticization is generated by friction, overheating can easily lead to scorched material

In the SPC / WPC flooring, PVC pipe, wall panels, resin tile and other highly filled products production process, the higher the filler, the product’s rigidity and shrinkage resistance performance is better, the price is more competitive. At the same time, this also puts forward higher requirements on the performance of PVC internal lubricant;

Polyester wax as PVC internal lubricant has natural advantages of compatibility and dispersibility and is more recommended for the production of highly filled PVC products. RALLYCHEM polyester wax RL-1118 is also more cost-effective than the common stearic acid.

RL-1118 is a polyester wax with a unique molecular structure designed by Rallychem Chemicals. As a special internal lubricant for PVC high filler, RL-1118 can replace stearic acid and show better internal lubrication performance. It avoids the defects of small molecule stearic acid which is easy to precipitate and brittle during PVC processing.

RL-1118 has a lower minimum torque relative to the common first grade stearic acid 1842, showing better internal lubrication and flow properties. It performs consistently with stearic acid 1842 in terms of plasticizing time and equilibrium torque, reducing customer testing costs and time.

Highly filled PVC formulations require higher levels of internal lubrication performance. While improving the dispersibility of calcium carbonate, it is necessary to avoid high friction heat that may lead to rapid stabilizer consumption and PVC decomposition. RL-1118 provides better wetting and coating of CaCO3, which results in better performance in high filler formulations.

Conventional stearic acid has a dropping point of 55-58°C, while polyester wax RL-1118 has a dropping point of 85°C. This is a very high dropping point for PVC products with high Vicat requirements. Higher Vicat softening points can be achieved with RL-1118 than with stearic acid formulations for PVC products.

You May Be Interested

Why Your Coatings Perform Better with Polyethylene Wax Additives?

2025 / 11 / 19

Why Polyethylene Wax Is the Key to High Performance Printing Inks

2025 / 11 / 18

[Exhibition Invitation] RALLYCHEM · Sincerely Invites You to Attend CHINACOAT 2025

2025 / 11 / 14

[Exhibition Invitation] Countdown to Plastics & Rubber Indonesia 2025 – RALLYCHEM Looks Forward to Meeting You

2025 / 11 / 07

[Exhibition Review] Empowering New Materials, Shaping a Shared Future — RALLYCHEM Successfully Showcased at the 2025 China Plastics Additives Annual Conference

2025 / 11 / 07