Differences between twin-screw extruders and single-screw extruders in PVC processing

Twin-screw extruder is the most common machinery in the modified plastics industry, widely used in the polymer processing industry and other production and processing areas; Twin-screw extruder variety, can be divided into two major categories of engaging and non-engaging, engaging twin-screw extruder can be divided into two major categories of isotropic and heterotropic rotation.

The structure and function of isotropic twin-screw extruder is very similar to that of single-screw extruder, but there are great differences in the working principle. Mainly in the following aspects:

Twin-screw extruder can be divided into anisotropic twin-screw and isotropic twin-screw according to the difference of the direction of rotation of the two screws.

The meshing co-rotating twin-screw extruder is widely used in the physicochemical modification of matrix resin, such as filling, reinforcing, toughening, reaction extrusion, and so on.

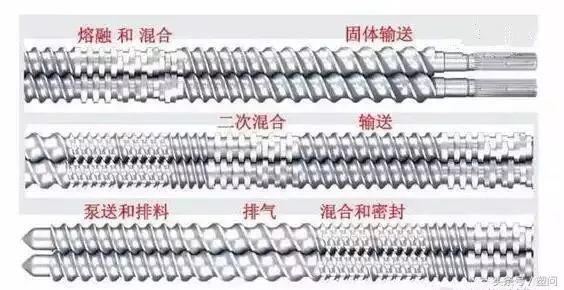

With a variety of raw materials dispersed mixing-based mixing should be used isotropic twin-screw extruder, and the above figure shows the speed vector of the isotropic twin-screw into each other in reverse, so the isotropic rotation of the twin-screw and isotropic rotation of the twin-screw compared to the shear effect of its much larger, unsuitable for the mixing and molding of PVC.

Commonly used in blended filler plastics is powdered calcium carbonate, talcum powder, titanium dioxide, general filler amount of 30% to 60%, filler masterbatch up to 80%. As the powdered filler contains a large amount of air, in the screw kneading area of the mixing air will be separated out, resulting in the reverse flow of materials into the screw groove, affecting the positive conveyance of the powder, and ultimately reduce the amount of extrusion.

Application examples of twin-screw extruder: glass fiber reinforced, fuel-retardant granulation (such as PA6, PA66, PET, PBT, PP, PC enhanced flame retardant, etc.); high filler granulation (such as PE, PP filled with 75% CaCO3.); heat-sensitive materials pelletizing (such as PVC, XLPE cable materials); thick color masterbatch (such as 50% filled with pigmented powder); anti-static masterbatch, alloys, color, low filler blending granulation; cable materials; cable materials; cable materials; cable materials. Filling co-blending granulation; cable material granulation (such as sheath material, insulation material); XLPE pipe material granulation (such as masterbatch for hot water cross-linking); thermosetting plastics mixing and extrusion (such as phenolic resins, epoxy resins, powder coatings); hot-melt adhesive, PU reaction extrusion granulation (such as EVA hot-melt adhesive, polyurethane); K resins, SBS de-volatilization granulation and so on.

Due to the complexity of the structural design and processing of the twin-screw extruder, the theoretical development is not perfect, but the combined design of the isotropic twin-screw extruder can be arranged and combined with a variety of geometrical shapes of the threaded elements and barrel elements, and according to the experience-theoretical-practical-inspection, so that it can be optimized for the different mixing requirements to adapt to the needs of different process formulas, which makes the isotropic twin-screw extruder has a very strong Adaptability. Mainly in the following aspects:

What is the input principle of an anisotropic twin-screw extruder?

In an anisotropic twin-screw extruder, the material is conveyed with a positive displacement similar to that in a gear pump. Anisotropic twin-screw extruder has a low rotational speed, low shear heat generation of the material, and the material is not easy to decompose, so it does not require high thermal stability of the material, and it is especially suitable for molding and processing of heat-sensitive materials (e.g., PVC). Compared with the isotropic twin-screw extruder, the isotropic twin-screw extruder has higher conveying efficiency, better exhaust effect and melting effect, although the material dispersion and mixing effect is poorer than that of the isotropic twin-screw extruder, but the ability to establish a stable pressure in the head is stronger, and therefore it is more suitable for extruding products directly. In addition to the use of anisotropic twin-screw extruder instead of a single-screw extruder, you can eliminate the pre-plasticization granulation process, direct extrusion processing of PVC powder, so that the cost of products down. Anisotropic rotary twin-screw extruder is mainly used for extruding PVC pipes. Profiles, plates and pelletizing. Parallel anisotropic twin-screw extruder has also begun to be used in large-scale HDHDPE pipe production line.

Anisotropic conical twin-screw extruder is traditionally used in the extrusion of PVC products, but in recent years there have been domestic examples of the application of anisotropic conical twin-screw extruder to the extrusion of polyolefin pipes, and practice has shown that it has been largely successful. The purpose of this practice is to save energy. A 65 body 132umum conical twin-screw extruder, drive motor power is only 37kW, in the extrusion of polyethylene pipe, pipe specifications and output can be equivalent to a 75mm or even 80mm single-screw extruder, and generally a 75mm or 80mm single-screw extruder, the drive power of the least is 90kW. foreign countries already have a ready-made parallel anisotropic twin-screw extruder extrusion products mature. Foreign countries already have mature experience in extruding products with parallel anisotropic twin-screw extruder, the domestic alternative to use anisotropic conical twin-screw extruder in fact, or for the consideration of the cost of the equipment, parallel anisotropic twin-screw extruder manufacturing costs higher than that of the anisotropic conical twin-screw extruder.

This method of use is certainly not a simple alternative, after all, polyethylene melt and PVC melt flow performance has obvious differences, so for the extrusion of PVC products for the anisotropic conical twin-screw extruder, the need to redesign the screw can be used for the extrusion of polyethylene; and the head should also be modified accordingly. In recent years, some people try to extrude products with isotropic twin-screw extruder (including conical twin and flat twin), and some progress has been made, but I think that from the point of view of energy saving, there is no great difference between isotropic and anisotropic twin-screw, and it is more difficult for isotropic twin-screw extruder to establish a stable pressure of the head, which is not as easy as adopting anisotropic twin-screw directly.

The main differences between anisotropic twin-screw extruder and single-screw extruder are the following two points:

You May Be Interested

PVC Pipe & Profile Processing: Why Heat Stabilizers Are Essential—and Why Wax Additives Inside Stabilizer Packages Matter

2026 / 02 / 24

What Does “High Density” Mean in Oxidized Polyethylene Wax?

2026 / 02 / 17

How Polyethylene Wax Enhances Pigment Dispersion and Color Consistency in Masterbatch Production

2026 / 02 / 05

Cost Optimization in PVC Processing: Using Targeted Polyester Wax to Partially Replace Stearic Acid and Paraffin Wax

2026 / 02 / 04

Engineering Plastics Lubrication: Why Polyester Wax is the Montan Wax Alternative

2026 / 01 / 23